Mold Design & Manufacturing

DESIGN | |

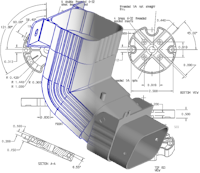

Utilizing high-end CAD/CAM systems specialized in the design and manufacture of molds, Petrolia Plastics Inc. is capable of designing tools capable of producing almost any plastics part. The use of advanced mold-design technology is greatly enhanced by over 40 man-years of technical expertise in mold design. Petrolia's mold designers have produced tools ranging from basic, ultra-high-volume tools for the gas and oil industry, to the most sophisticated tooling needed to meet the requirements of advanced and specialized automotive components. |

|

PROTOTYPING | |

By utilizing computer technology, highly skilled engineers and moldmakers and high performance machining equipment, a sample of the part can be made. This allows testing of the physical part to see if it meets the customer's requirements before the mold is built. A complete 3D computer drawing can be turned into a test part by using rapid prototyping techniques. A 3D part file is sent, in security, to an outside rapid prototyping facility and a solid part is returned which can then be used to verify general shape and aesthetic qualities including paint and texture. |

|

3D VISUALIZATION | |

Petrolia can create a 3D visual representation of how a finished product might look. Graphics software is utilized to construct accurate representations of plastic components before the mold is even built including InMold Decorative printing. |

|

RESEARCH & DEVELOPMENT | |

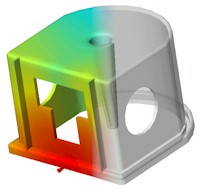

Petrolia can do the necessary research to determine how an idea or product might be manufactured, what the best materials and processes might be and whether the project is feasible. Petrolia Plastics Inc. has concentrated on R & D to develop leading edge processes and capabilities to provide efficient, cutting-edge solutions for their customers. Techniques including mold-flow analysis combined with part and process prototyping allow us turn design ideas into functional plastic products. |

|

TOOL CONSTRUCTION & MAINTENANCE | |

Petrolia’s fully equipped toolroom has gained the respect of design engineers with Tier One and Two suppliers in the automotive industry and several other reputable organizations in the electronics and high-tech areas. Petrolia custom builds all its own tooling to the highest standards that enables the development of multi-cavity tools that produce millions of parts per year. The toolroom utilizes orbit NC EDM and a high-speed machining center that provides our customers with shorter lead times on tooling projects. |

|

|  | ||

|

|

| |

|  |

All types of CAD/CAM or artwork files can be accommodated. File and media types supported by Petrolia are listed below. Arrangements can be made, upon request, to transfer formats of electronic information not included in this list.

|  | ||

|

|

| |

|  |

| CAD/CAM File Formats IGES Initial Graphics Interchange Specification (.igs, .iges) |

| DXF Autocad Drawing Interchange File (.dxf) |

| VDA VDA Surface Interface (.vda) |

| PTC Pro/Engineer Neutral File (.neu) |

| SLA Stereo Lithography File (.sla, write only) |

| SAT ACIS (.sat) |

| PFM Native Cimatron File (.pfm) |

Artwork from most illustration software such as Adobe Illustrator, CorelDraw!, can also be accepted, as well as other applications that support Encapsulated Postscript (EPS) files.

|  | ||

|

|

| |

|  |

| DAT DDS-1 & DDS-2 (Unix) |

| DAT DDS-1, DDS-2, DDS-3 (Windows NT) |

| 3.5" & 5.25" Diskette (Any platform) |

| 100MB and 250MB Zip Disk(PC or Mac) |

| CD-ROM (Any platform) |

| 1/4" Cartridge (Unix) |

| Mac Diskette (High Density) |

Petrolia can also retrieve files sent via email or anonymous FTP.

|  | ||

|

|

| |

|  |

| PK-ZIP (.zip) |

| GNUzip[gzip] (.gz) |

| TAR (.tar) |

| Unix "compress" (.Z) |

| Uuencoded (.uue) |

| Mac BinHex or Stuffit (hqx,sit) |

| ARJ, LHA & ARC (.arj, .lha, .arc) |